Shengda Ceramic provide all kinds of Zirconia Ceramic Engineering Ceramic.

Product Introduction

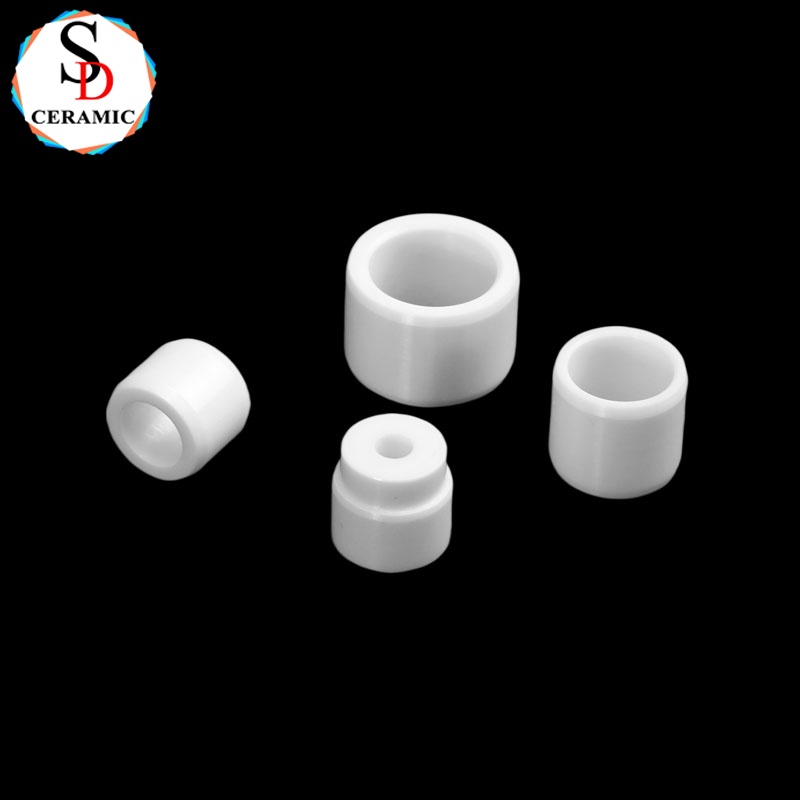

Our white zirconium oxide (ZrO₂) ceramic cylinders offer exceptional strength, wear resistance, and thermal stability, making them ideal for demanding industrial, medical, and electronic applications. With a smooth, polished finish and superior mechanical properties, these zirconia cylinders outperform traditional materials in harsh environments.

﹡Key Features

✔ High Strength & Toughness – 3* stronger than alumina ceramics

✔ Excellent Wear Resistance – Ideal for abrasive environments

✔ Low Thermal Conductivity – Minimizes heat transfer

✔ Biocompatible & Corrosion-Resistant – Safe for medical and chemical uses

✔ Precision Machining – Tight tolerances (±0.005mm) for critical applications

﹡Technical Specifications

Material: 99% Yttria-Stabilized ZrO₂

Density: 6.0 g/cm³

Hardness: 1200 HV

Flexural Strength: 1000-1200 MPa

Max. Operating Temp.: 1500°C

|  |  |

﹡Applications

Medical Implants & Surgical Tools (biocompatible & sterilizable)

Precision Bearings & Bushings (low friction, high durability)

Electronics & Sensors (excellent electrical insulation)

Industrial Wear Parts (pumps, valves, and guides)

﹡Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

﹡Certifications

﹡Company

Yixing Shengda Refractory Ceramic Co, Ltd. was established in Yixing City, China in 1995, witha production area of over 10,000m2. lt is an enterprise specializing in the production of aluminaceramic,zirconia ceramic,slicon nitride, silicon carbide and other precision ceramic products.

And we also produce ceramic band heaters, ceramic terminal block, cordierite and mullite ceramic parts an other ceramic products.

﹡Ceramic Properties

| Properties | Units | Cordierite Ceramic | Mullite Ceramic | 95%Alumina Ceramic | 99%Alumina Ceramic | 99.5%Alumina Ceramic | 99.7%Alumina Ceramic | Silicon Nitride | Zirconia Ceramic |

| Colour | Yellow | White | White | Light yellow | Light yellow | Light yellow | Black | White | |

| Density | g/cm3 | 1.9 | 2.6 | 3.6 | 3.8 | 3.8 | 3.9 | 3.2 | 6 |

| Flexural Strength | Mpa | 30 | 120 | 300 | 350 | 375 | 375 | 800 | 1100 |

| Compressive Strength | MPa | 350 | 500 | 2500 | 2800 | 2800 | 2554 | 2600 | 3000 |

| Modulus of Elasicity(20℃) | Gpa | 40 | 100 | 300 | 350 | 350 | 357 | 290 | 320 |

| Max Use Temperature | °C | 1200 | 1300 | 1400 | 1500 | 1500 | 1760 | 1300 | 1050 |

| Thermal Condutivity | W(m.K) | 1.3-1.8 | 2~6 | 20 | 30 | 30 | 33-38 | 25 | 3 |

| Thermal Expansion Cofficient | 10-6/°C | 2.5-3 | 2.5-3 | 7.5 | 8 | 8.2 | 8.2 | 3 | 10 |

| Thermal Shock Resistance | △T℃ | 300 | 150 | 140 | 150 | 200 | 223 | 600 | 250 |

| Dielectric Strength | KV/mm | - | - | 15 | 18 | 18 | 23.4 | 14 | 15 |

| Dielectric Constant | Er | 8 | 8 | 9 | 9.2 | 9.2 | 9.84 | 9 | 26 |

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : White Zirconium Oxide Ceramic Parts Shining Small Zirconia Cylinder

If you have any questions or need help, feel free to contact with our team.

Phone

+86 183 5248 9056

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By