Aluminum oxide ceramic (Al₂O₃) is the most widely used advanced ceramic material, which has become a core material in industrial, electronic, medical and other fields due to its high hardness, excellent wear resistance,high temperature resistance and electrical insulation.

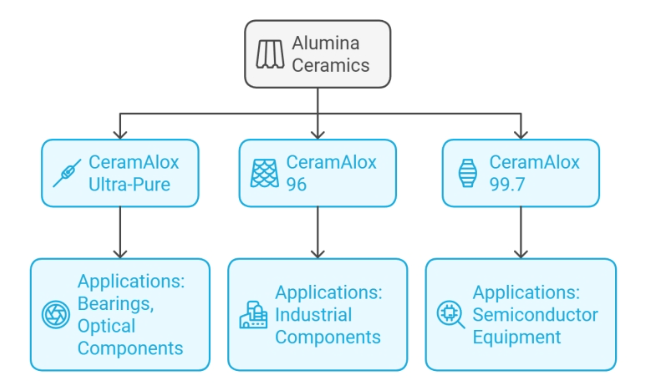

1. Regarding alumina ceramics (Al₂O₃)

Aluminum oxide ceramics are ceramic materials mainly composed of aluminum oxide (Al₂O₃),

which can be divided into multiple grades according to their purity:

99% alumina ceramic: with the best high-temperature stability (1600 ℃), used for crucibles, refractory furnace tubes, and high-precision bearings.

95% -96% alumina ceramics: High cost performance, suitable for wear-resistant liners, electronic substrates, and chemical seals.

85% alumina ceramic: with moderate mechanical strength, commonly used in insulation parts and textile guides.

Color and Density:

95% -96% Al₂O₃: milky white, density 3.7-3.8 g/cm ³

99% Al₂O₃: light yellow, density 3.8-3.9 g/cm ³

|  |

2. Performance characteristics of alumina ceramics

(1) Mechanical performance

The hardness is second only to diamond, and the wear resistance is more than 5 times that of high carbon steel

Compressive strength up to 2000-3000 MPa, suitable for high load environments

(2) Thermal properties

High temperature resistance: Long term use temperature up to 1600 ℃ (short-term 1800 ℃)

Low thermal expansion: coefficient of thermal expansion 8.5 × 10 ⁻⁶/° C (20-1000 ℃)

Thermal conductivity: 24-30 W/(m · K) (96% purity), excellent heat dissipation performance

(3) Electrical characteristics

Insulation: Volume resistivity>10 ¹⁴Ω· cm (room temperature)

Dielectric strength: 15-20 kV/mm, suitable for high-voltage insulation components

High frequency stability: dielectric constant 9.8@1MHz Suitable for RF components

(4) Chemical stability

Corrosion resistance: resistant to strong acids and alkalis (except hydrofluoric acid), stable at pH 1-14

Biocompatibility: FDA certified for use in food and medical devices

3. Typical applications of alumina ceramics

(1) Industrial sector

Wear resistant components: mining conveying liner, mud pump sealing ring

High temperature equipment: thermocouple protection tube, molten metal guide groove

Mechanical seals: ceramic shaft sleeves and valve components for chemical pumps

(2) Electronic power

Circuit board: LED heat dissipation board, power module insulation layer

Vacuum components: electronic tube insulation ring, high-voltage switch arc extinguishing chamber

(3) Medical and consumer goods

Medical implants: artificial joints, dental restoration abutments

Daily necessities: high-end cutting tools, watch mirrors

4. Future Development Trends

Nano alumina: improves toughness to 6 MPa · m ² (particle size<100nm)

Transparent alumina: laser window, high-pressure sodium lamp tube (transmittance>70%)

3D printing technology: integrated molding of complex structured ceramic parts

Summary

Alumina ceramics, with their excellent comprehensive performance, are irreplaceable in harsh working conditions such as high temperature, wear resistance, and insulation. With the advancement of material technology, its application fields are still continuously expanding!

If you have any questions or need help, feel free to contact with our team.

Phone

+86 183 5248 9056

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By