Cordierite Ceramic is widely used for kiln furniture, welding, foundry and casting applications, where temperatures is high and rapid temperature changes take place.

Product Introduction

Product Overview

Our high-purity Cordierite Ceramic Blocks are engineered to withstand rapid temperature changes (up to 1,300°C) without cracking, making them ideal for kilns, furnaces, and catalytic converters. Custom sizes available for OEM applications.

Key Technical Specifications

Material Composition: 2MgO·2Al₂O₃·5SiO₂ (Low-iron formula)

Thermal Shock Resistance: ΔT >800°C (Water quenching test)

Max Service Temperature: 1,350°C (2,462°F) continuous use

CTE (25–800°C): 1.5–2.0×10⁻⁶/°C (Ultra-low expansion)

Porosity: <1% (Dense sintered structure)

Dielectric Strength: 8–12 kV/mm

Standard Sizes: 100×100mm to 500×500mm (Custom dimensions ±0.5mm tolerance)

Industry Applications

1. Automotive & Catalytic Converters

Used as honeycomb substrates for catalytic converters (resists exhaust gas thermal cycling)

2. High-Temperature Furnaces

Kiln furniture (saggers, setters) for ceramic/powder metallurgy processing

3. Glass Manufacturing

Thermocouple protection tubes in glass melting tanks

4. Semiconductor Equipment

Wafer processing components requiring low thermal expansion

5. Thermal Processing

Heat exchanger plates for regenerative burners

Why Choose Cordierite Blocks?

✔ Unmatched Thermal Stability – Withstand 100+ rapid thermal cycles (1,000°C⇄RT)

✔ Custom Machining – Laser-cut, drilled, or CNC-machined to your drawings

✔ Chemical Resistance – Excellent acid/alkali resistance (except HF)

✔ Cost-Effective – Longer service life than mullite or alumina alternatives

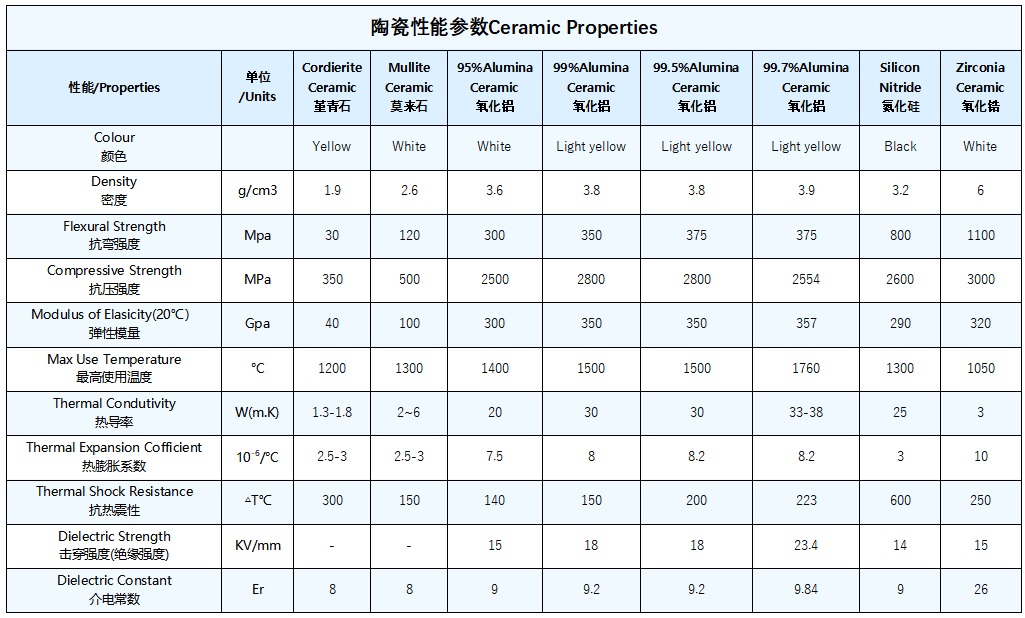

Technical Parameters

Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

Certifications

Packaging and shipping

FAQ:

Q: How can I get the after-service?

A: Any quality problem, feel free to contact us, we’ll deal with it within 3 working days.

Q:What kind of transportation mode do you have?

A: By Sea/By Train/By Air or By Express, 15-20days Against Deposit.

Q: How is your price level?

A: Factory direct sale, we have whole production line work process from platform to main parts. We have hot injection machine and dry pressing machine.

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : Custom Sized Excellent Thermal Shock Resistance Cordierite Ceramic Blocks

If you have any questions or need help, feel free to contact with our team.

Phone

+86 183 5248 9056

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By