Silicon Nitride Ceramic is a man-made compound. Parts are pressed and sintered. The material is dark grey to black and can be polished to a very smooth reflective finish.

Product Introduction

Key Features & Technical Specifications

Our Silicon Nitride Ceramic Strips (Si3N4) are engineered for extreme environments, offering unmatched thermal shock resistance, high strength, and exceptional wear resistance. These precision components are ideal for industries requiring reliability under thermal cycling and mechanical stress.

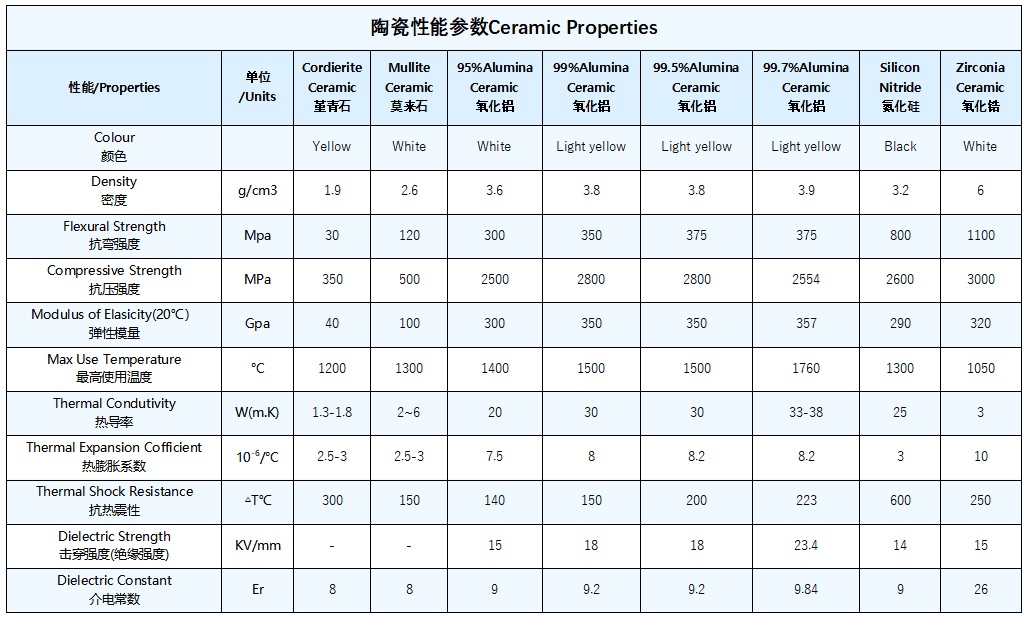

Technical Parameters:

Material: High-purity Silicon Nitride (Si3N4)

Density: ≥3.2 g/cm³

Flexural Strength: 800-1000 MPa

Fracture Toughness: 6-7 MPa·m¹/²

Thermal Conductivity: 20-30 W/m·K

Thermal Expansion Coefficient: 3.2 × 10⁻⁶/°C (RT-1000°C)

Maximum Operating Temperature: 1400°C (in inert atmosphere)

Electrical Resistivity: >10¹⁴ Ω·cm

Surface Finish: As-sintered, polished, or coated (optional)

|  |

Why Choose Silicon Nitride Ceramic Strips?

✔ Superior Thermal Shock Resistance – Withstands rapid temperature changes without cracking, perfect for high-heat applications.

✔ Exceptional Mechanical Strength – Maintains structural integrity under extreme loads and vibrations.

✔ Wear & Corrosion Resistant – Ideal for harsh chemical and abrasive environments.

✔ Customizable Dimensions – Available in various thicknesses, widths, and lengths to fit specific needs.

Industry Applications

1. Semiconductor & Electronics Manufacturing

Used as wafer handling arms, heater plates, and insulation components in CVD/PVD systems, where high purity and thermal stability are critical.

2. Automotive & Aerospace

Turbocharger components – Silicon nitride’s low density and high strength reduce rotational mass, improving efficiency.

Bearings & wear parts – Performs reliably in high-speed, high-temperature engine environments.

3. Metal Processing & Foundry

Thermocouple protection tubes – Resists molten metal splashes and thermal cycling.

Welding & brazing fixtures – Maintains dimensional stability under repeated heating.

4. Industrial Wear Components

Cutting tools, nozzles, and guides – Outlasts traditional materials in abrasive conditions.

Custom Ceramics Solutions

We specialize in precision-engineered Si3N4 ceramic parts tailored to your exact specifications. Whether you need thin ceramic strips for sensors or complex-shaped components for high-temperature systems, our advanced manufacturing ensures optimal performance.

Conclusion

Our Silicon Nitride Ceramic Strips deliver unmatched durability, thermal stability, and precision for the most demanding industrial applications. With customizable options and rigorous quality control, we provide solutions that outperform traditional materials.

Technical Parameters

Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

Certifications

Our customers

Packaging and shipping

Transport

FAQ:

Q: Do you have the products in stock?

A: Some standard produce have in stock, such as ceramic band heater insulator; bobbin heater insulator and ceramic connector. But it needs to check according to your requirement.

Q: How do you pack the goods?

A: Our standard packaging is carton, we can customize it as per your requirement as well.

Q: How many days do you finish the sample?

A: Usually 15 business days (Including 8days for making furnaces and 7days for producing samples)

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : Superior Thermal Shock Resistance Precision Silicon Nitride Ceramic Strips

If you have any questions or need help, feel free to contact with our team.

Phone

+86 183 5248 9056

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By