Magnesium oxide ceramics are ceramic materials that contain at least 90% magnesium oxide (MgO).

Product Introduction

Magnesium oxide ceramics are ceramic materials that contain at least 90% magnesium oxide (MgO).

It has good mechanical strength and works well when uniformly heated or cooled and thermal shock is avoided.Performance is better than alumina, stable at 2200℃.

However, above this temperature creep occurs. Because of its resistance to lead-based materials, it is used in the processing of piezoelectric materials, and used in thermocouples as well as in various heating appliances.

The MgO here insulates the heating elements from one another and the metal sheath, but at the same time ensures good thermal conductivity to the outside.

Main Features:

1. High hardness

2. High heat resistance

3. Good wear resistance

4. High electrical resistivity

5. High corrosion resistance

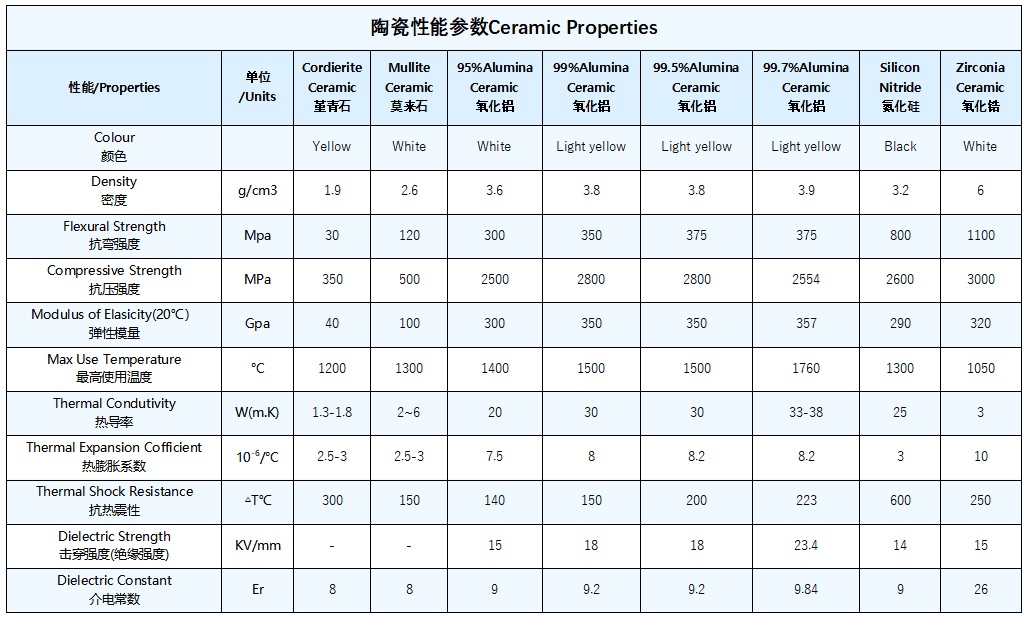

Technical Parameters

Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

Certifications

Our customers

Packaging and shipping

Transport

FAQ:

Q: Do you have the products in stock?

A: Some standard produce have in stock, such as ceramic band heater insulator; bobbin heater insulator and ceramic connector. But it needs to check according to your requirement.

Q: How do you pack the goods?

A: Our standard packaging is carton, we can customize it as per your requirement as well.

Q: How many days do you finish the sample?

A: Usually 15 business days (Including 8days for making furnaces and 7days for producing samples)

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : Magnesia Ceramic Pipes MgO Ceramic Tubes

If you have any questions or need help, feel free to contact with our team.

Phone

+86 183 5248 9056

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By