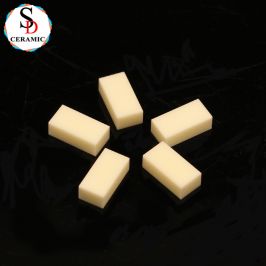

Our 99% purity alumina ceramic (Al2O3 ceramics) components are engineered for extreme environments, offering exceptional wear resistance, electrical insulation, and thermal stability up to 1500°C. Customizable for your specific machinery requirements.

Product Introduction

Premium Al₂O₃ Ceramic Blocks for Extreme Environments

Our 99% Alumina Ceramic Block (Al₂O₋) is engineered for maximum wear resistance, corrosion protection, and thermal stability in harsh industrial applications. As a leading manufacturer of alumina ceramics, we provide high-purity ceramic blocks that outperform metals, polymers, and lower-grade ceramics in durability and longevity.

Industrial Applications & Case Studies

1. Mining & Mineral Processing – Wear Protection

Problem: Steel chutes and liners wear out quickly in abrasive slurry environments.

Solution: Our alumina ceramic blocks are used as:

Slurry pump liners

Cyclone separator wear plates

Hopper and chute linings

Result: A mining company reported 10x longer lifespan compared to hardened steel, reducing downtime by 70%.

2. Power Plants – Abrasion & Corrosion Resistance

Coal Handling Systems: Ceramic blocks in pulverizer wear plates

Flue Gas Desulfurization (FGD): Liners for corrosive slurry flow

Ash Handling: Impact-resistant ceramic blocks for conveyor systems

3. Steel & Foundry – High-Temperature Stability

Ladle Liners: Withstand molten metal splashes

Burner Nozzles: Resistant to thermal shock

Roller Guides: For continuous casting machines

4. Chemical Processing – Corrosion Resistance

Reactor Linings: Acid-resistant Al₂O₃ ceramic blocks for HCl, H₂SO₄ environments

Pump Casings: For abrasive chemical slurries

|  |

Why Choose Alumina Ceramic Blocks?

✔ Superior Wear Resistance

10x harder than steel (1600 HV vs. 200-800 HV for metals)

Ideal for abrasive particle impact (sand, coal, ores)

✔ Extreme Temperature Stability

No deformation up to 1650°C

Low thermal expansion minimizes cracking

✔ Chemical Inertness

Resists acids, alkalis, and solvents

No corrosion in harsh chemical environments

✔ Custom Engineering Support

Prototyping & Testing: We validate performance before mass production

Fast Turnaround: Standard sizes in stock, custom blocks in 2-4 weeks

Ceramic Properties

| Properties | Units | Cordierite Ceramic | Mullite Ceramic | 95%Alumina Ceramic | 99%Alumina Ceramic | 99.5%Alumina Ceramic | 99.7%Alumina Ceramic | Silicon Nitride | Zirconia Ceramic |

| Colour | Yellow | White | White | Light yellow | Light yellow | Light yellow | Black | White | |

| Density | g/cm3 | 1.9 | 2.6 | 3.6 | 3.8 | 3.8 | 3.9 | 3.2 | 6 |

| Flexural Strength | Mpa | 30 | 120 | 300 | 350 | 375 | 375 | 800 | 1100 |

| Compressive Strength | MPa | 350 | 500 | 2500 | 2800 | 2800 | 2554 | 2600 | 3000 |

| Modulus of Elasicity(20℃) | Gpa | 40 | 100 | 300 | 350 | 350 | 357 | 290 | 320 |

| Max Use Temperature | °C | 1200 | 1300 | 1400 | 1500 | 1500 | 1760 | 1300 | 1050 |

| Thermal Condutivity | W(m.K) | 1.3-1.8 | 2~6 | 20 | 30 | 30 | 33-38 | 25 | 3 |

| Thermal Expansion Cofficient | 10-6/°C | 2.5-3 | 2.5-3 | 7.5 | 8 | 8.2 | 8.2 | 3 | 10 |

| Thermal Shock Resistance | △T℃ | 300 | 150 | 140 | 150 | 200 | 223 | 600 | 250 |

| Dielectric Strength | KV/mm | - | - | 15 | 18 | 18 | 23.4 | 14 | 15 |

| Dielectric Constant | Er | 8 | 8 | 9 | 9.2 | 9.2 | 9.84 | 9 | 26 |

Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

Certifications

Our customers

Packaging and shipping

Transport

FAQ:

Q: Do you have the products in stock?

A: Some standard produce have in stock, such as ceramic band heater insulator; bobbin heater insulator and ceramic connector. But it needs to check according to your requirement.

Q: How do you pack the goods?

A: Our standard packaging is carton, we can customize it as per your requirement as well.

Q: How many days do you finish the sample?

A: Usually 15 business days (Including 8days for making furnaces and 7days for producing samples)

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : Wear Resistantance 99 Alumina Ceramic Block for Industrial Applications

If you have any questions or need help, feel free to contact with our team.

Phone

+86 183 5248 9056

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By