Zirconia ceramic (ZrO₂) is a high-performance structural ceramic known for its ultra-high toughness, excellent wear resistance, biocompatibility, and high temperature resistance. It is widely used in medical, industrial, electronic, and other fields.

About Zirconia Ceramics (ZrO₂)

Zirconia ceramics (ZrO₂) are phase transition toughened ceramics that form stable tetragonal (TZP) or cubic (CSZ) structures by adding stabilizers (such as Y₂O₃, CeO₂), allowing them to maintain high hardness while possessing metallic grade fracture toughness.

Color and density of zirconia

3Y-TZP (white, 6.05 g/cm ³): Medical grade, best biocompatibility

Ce TZP (ivory color, 5.8 g/cm ³): high toughness, suitable for industrial wear-resistant parts

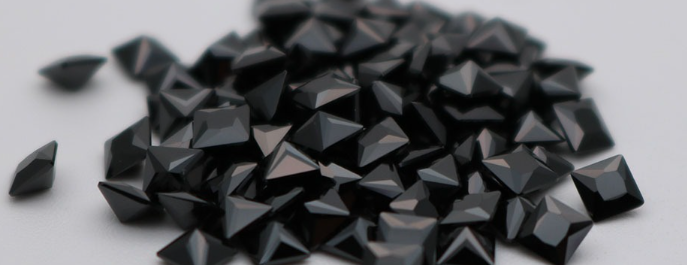

Black zirconia: added with special coloring agent, used for high-end consumer goods

Performance characteristics of zirconia ceramics

1. Mechanical properties

Ultra high toughness (8-15 MPa · m ², three times that of alumina)

High hardness (Hv1.200-1400, close to sapphire)

Bending strength (900-1200 MPa, better than most metals)

2. Thermal properties

High temperature resistance (long-term use at 1500 ℃, short-term up to 2000 ℃)

Low thermal conductivity (2-3 W/m · K, suitable for insulation applications)

The coefficient of thermal expansion is close to that of metals (10.

5 × 10 ⁻⁶/° C, convenient for composite use with metals)

3. Electrical characteristics

Excellent insulation performance (volume resistivity>10 ΩΩ· cm)

Oxygen ion conductivity (for solid oxide fuel cell electrolytes)

4. Chemical stability

Acid and alkali corrosion resistance (except hydrofluoric acid, pH 1-14 stable)

Biological inertness (non-toxic, FDA certified for human implantation)

The use of zirconia ceramics

1. Medical field

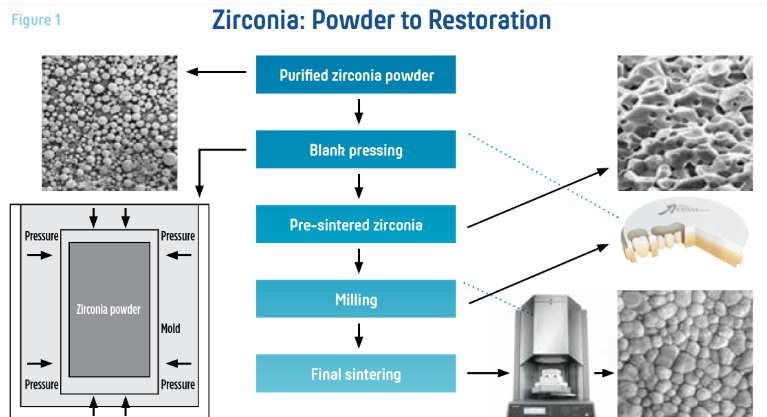

Dental implants (all ceramic crowns, implant abutments)

Artificial joints (hip and knee prostheses)

2. Industrial sector

Mechanical seals (chemical pumps, compressors, lifespan increased by 5 times)

Ceramic bearings (non-magnetic, corrosion-resistant, used for precision instruments)

Wear resistant lining plate (for mining and power industry transmission systems)

3. Electronics and Energy

Oxygen sensor (automotive exhaust detection)

Solid Oxide Fuel Cell (SOFC) Electrolyte

4. Consumer goods

High end watch components (wear-resistant, lightweight)

Smartphone Backboard (with excellent 5G signal penetration)

Future Development Trends

Nano zirconia: improves fracture toughness to 20 MPa · m ²

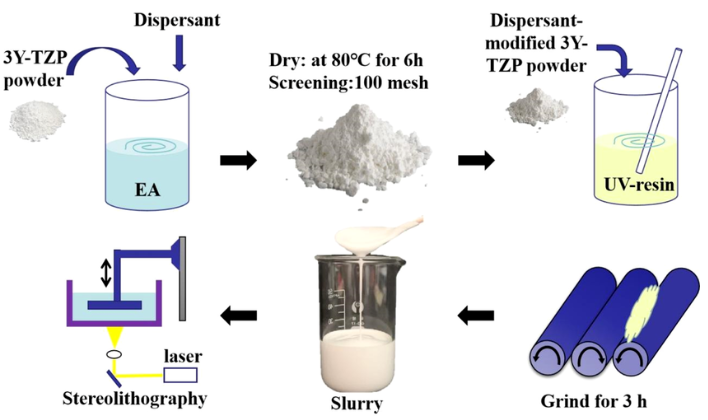

3D Printing Zirconia: Customization of Complex Structure Medical Implants

Transparent zirconia: laser windows, optical devices

|  |

Zirconia ceramics, with their excellent comprehensive performance, are gradually replacing metals and traditional ceramics, becoming the preferred material for high-end industrial and medical applications.

If you have any questions or need help, feel free to contact with our team.

Phone

+86 183 5248 9056

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By