Mullite ceramic (3Al₂O₃·2SiO₂) is a high-performance ceramic material mainly composed of alumina and silica. Due to its excellent thermal shock resistance, high temperature stability, low thermal expansion coefficient, and good mechanical strength, mullite ceramics are widely used in refractory materials, electronic packaging, aerospace and other fields.

1. What is mullite ceramic?

Mullite ceramic is a composite oxide ceramic composed of aluminum oxide (Al₂O₃) and silicon dioxide (SiO₂), with a chemical formula of 3Al₂O₃ · 2SiO₂. It is renowned for its excellent high-temperature performance, low thermal conductivity, and outstanding thermal shock resistance, making it an ideal material for high-temperature environments.

Mullite ceramics are usually made by sintering high-purity alumina and silicon sources (such as kaolin or silicon micro powder), and can be formed by processes such as injection molding, dry pressing, or isostatic pressing. Compared with alumina ceramics, mullite ceramics have a lower coefficient of thermal expansion, making them perform better in environments with rapid temperature changes.

2. Classification of Mullite Ceramics

According to the differences in composition and microstructure, mullite ceramics can be divided into the following categories:

Pure mullite ceramics: synthesized from high-purity Al₂O₃ and SiO₂, with the best high-temperature performance.

Mullite zirconia composite ceramics: Adding zirconia to improve toughness and thermal shock resistance.

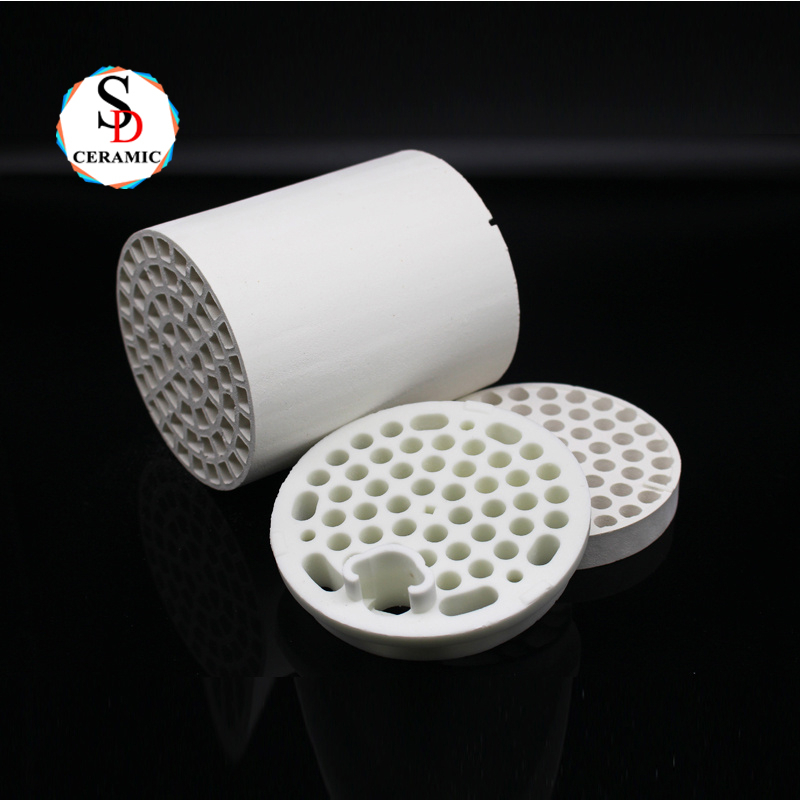

Porous mullite ceramics: with low density and excellent thermal insulation properties, suitable for high-temperature filtration and insulation materials.

3. Characteristics of Mullite Ceramics

High temperature stability: Mullite ceramics can maintain stable physical and chemical properties below 1600 ° C.

Low thermal expansion coefficient: making it less prone to cracking in high-temperature cycling environments.

Good thermal shock resistance: able to withstand drastic temperature changes without cracking.

Excellent corrosion resistance: It has high resistance to acids, alkalis, and molten metals.

High mechanical strength: It can maintain good bending and compressive strength even at high temperatures.

|

|

4. Application of Mullite Ceramics

Refractory materials: used for lining kilns, hot air ducts, and high-temperature components in the metallurgical industry.

Electronic packaging: As an insulating material for integrated circuit substrates and electronic components.

Aerospace: Used for coating turbine engine blades and high-temperature insulation components.

Chemical industry: Manufacturing corrosion-resistant reactors and catalyst carriers.

Environmental protection field: used for high-temperature gas filtration and exhaust gas treatment systems.

5. Summary

Mullite ceramics have become an indispensable material in high-temperature industrial applications due to their unique high-temperature stability, low thermal expansion, and excellent thermal shock resistance. With the development of technology, the application prospects of mullite ceramics in the fields of new energy, electronics, and environmental protection will be even broader.

If you have any questions or need help, feel free to contact with our team.

Phone

+86 183 5248 9056

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By